Exploring the Benefits of Automation in Construction

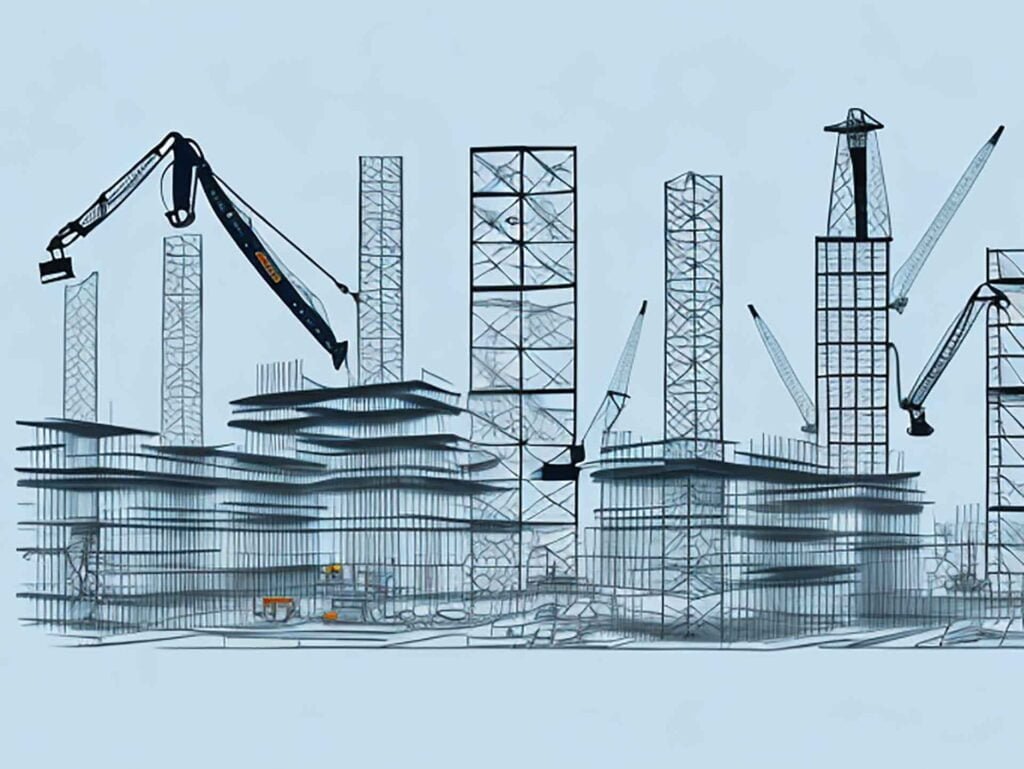

The construction industry is changing rapidly, and one of the most significant changes is the rise of automation. The use of advanced technologies and automated systems is revolutionizing the way buildings and infrastructure are designed, constructed, and maintained. In this article, we will explore the benefits of automation in construction, including efficiency and productivity improvements, cost savings, and enhanced safety and risk management.

The Rise of Automation in the Construction Industry

The construction industry has traditionally been viewed as one of the most labour-intensive sectors, with workers often exposed to dangerous conditions and tasks. However, the adoption of automation technologies is changing that perception, and this trend is expected to continue in the coming years.

As the world’s population grows, so does the demand for new buildings and infrastructure. However, the construction industry has been facing a labour shortage in recent years, making it difficult to meet the demand. Automation is seen as a solution to this problem, as it can help reduce the need for manual labour and improve efficiency.

A Brief History of Construction Automation

The use of automation in construction is not new. In fact, the ancient Egyptians used simple machines, such as ramps and levers, to build the pyramids. In more recent times, some tasks, such as demolition, excavation, and material handling, were automated. However, the latest technological advances are taking automation to the next level, with software, robotics, and sensors being used in different construction phases.

One of the earliest examples of modern construction automation was the use of tower cranes in the 1950s. These cranes were able to lift heavy loads and place them in precise locations, reducing the need for manual labour. Since then, automation has continued to evolve and expand in the construction industry.

Key Technologies Driving Automation

Several key technologies are driving automation in construction, including cloud computing, BIM, 3D printing, and drones. These technologies are streamlining processes, automate manual tasks, and improve collaboration between stakeholders.

Cloud computing allows project teams to share information and collaborate in real-time, improving workflows and decision-making processes. This technology also enables remote access to project data, making it easier for teams to work together across different locations.

BIM (Building Information Modelling) is an intelligent 3D model-based process that ensures the design, construction, and operation of buildings are efficient and effective. BIM software allows architects, engineers, and contractors to collaborate on a single, shared model, reducing errors and improving project outcomes.

3D printing is being used to create building components and spare parts on-site, improving supply chain management, and reducing lead times. This technology also allows for greater customization and flexibility in construction projects.

Drones are being used for surveying, inspection, and monitoring tasks, reducing manual labour, and improving safety. Drones can quickly and easily capture high-resolution images and data, providing valuable insights into construction sites.

Overall, the adoption of automation technologies in the construction industry is expected to continue to grow in the coming years. These technologies have the potential to improve efficiency, reduce costs, and enhance safety, making construction projects faster, safer, and more sustainable.

Improved Efficiency and Productivity

The construction industry has been transformed by the use of automation, which is improving efficiency and productivity in many ways. Here are some of the key benefits:

Reducing Manual Labour and Human Error

One of the most significant benefits of automation is the reduction of manual labour. By introducing robots, machines, and software programs, the construction sector can reduce the number of workers needed, lower labour costs, and improve safety. This is particularly important in hazardous or physically demanding tasks, such as heavy lifting or working at heights. Automation can also minimize human error, ensuring higher accuracy, and quality in work, which can lead to fewer mistakes and rework, saving time and money.

For example, in the construction of tall buildings, robots can be used to install and weld steel beams, eliminating the need for workers to do this manually. This reduces the risk of accidents and injuries, while also increasing productivity and efficiency. Similarly, drones can be used to survey construction sites, providing accurate data, and reducing the need for workers to do this manually, which can be time-consuming and error prone.

Streamlining Construction Processes

Construction projects are complex and require coordination and collaboration between different teams and stakeholders. Automation technologies are streamlining construction processes, enabling stakeholders to communicate better, and carry out tasks more efficiently. For example, automated monitoring systems can detect issues in real-time, allowing for faster resolution and preventing delays or errors that could impact the project’s outcome.

In addition, construction companies are using Building Information Modelling (BIM) to create digital models of buildings and infrastructure projects. BIM enables stakeholders to visualize and simulate different design options, identify potential issues, and optimize construction processes. This can lead to better decision-making, faster project completion, and improved quality of work.

Enhancing Project Management and Coordination

Automation is enhancing project management and coordination, bringing transparency and clarity into projects. Software solutions are providing real-time data and analytics, simplifying workflows, and reducing errors. This enables all stakeholders to access project data and monitor the project’s progress, mitigating potential risks and supporting decision-making processes.

For example, project management software can be used to track project timelines, budgets, and resources, allowing project managers to make informed decisions and adjust plans as needed. This can lead to better project outcomes, improved communication, and increased stakeholder satisfaction.

In conclusion, the use of automation in the construction industry is transforming the way projects are planned, designed, and executed. By reducing manual labour, streamlining construction processes, and enhancing project management and coordination, automation is improving efficiency and productivity, while also increasing safety and quality of work.

Cost Savings and Financial Benefits

The use of automation in construction can result in cost savings and financial benefits, which can be significant. By using automation, construction companies can achieve the following benefits:

- Lowering Labour Costs: Automation technologies can reduce the need for manual labour, thus reducing overall labour costs. In addition, some automation solutions, such as automated monitoring systems, can detect problems earlier, which can save money and time in resolving issues.

- Reducing Material Waste: Construction material waste is a significant problem in the sector, and it can result in substantial financial losses. Automation can help to minimize material waste by enabling precise and accurate construction, reducing the need for additional work, and ensuring better use of resources.

- Minimizing Project Delays and Overruns: Projects delays and overruns can be costly and can impact a project’s bottom line. Automation technologies can speed up construction processes and detect problems earlier, allowing for faster resolution. This can reduce project delays and mitigate potential financial losses.

By implementing automation technologies, construction companies can achieve significant cost savings and financial benefits. Here are some additional details on each of these benefits:

Lowering Labour Costs

Automation can help construction companies reduce the need for manual labour, which can be a significant cost saving. For example, using automated machinery to lay bricks can be much faster and more efficient than having workers lay bricks manually. This can reduce the overall labour costs for a project and free up workers to focus on other tasks.

In addition, some automation solutions, such as automated monitoring systems, can detect problems earlier. For example, if an automated monitoring system detects a problem with a piece of equipment, it can alert workers before the problem becomes more severe. This can save money and time in resolving issues and reduce the overall labour costs for a project.

Reducing Material Waste

Construction material waste is a significant problem in the sector, and it can result in substantial financial losses. Automation can help to minimize material waste by enabling precise and accurate construction. For example, using automated machinery to cut materials can be much more accurate than having workers cut materials manually. This can reduce the amount of material waste and ensure better use of resources.

In addition, automation can help to reduce the need for additional work. For instance, when a construction project demands a particular material type, an automated system can guarantee precise material quantities, minimizing the necessity for extra labour and promoting efficient resource utilization.

Minimizing Project Delays and Overruns

Project delays and overruns can be costly and can impact a project’s bottom line. Automation technologies can speed up construction processes and detect problems earlier, allowing for faster resolution. For example, using automated machinery to lay concrete can be much faster than having workers lay concrete manually. This can reduce the time it takes to complete a project and minimize potential delays and overruns.

In addition, automation can help to detect problems earlier. For example, if an automated monitoring system detects a problem with a piece of equipment, it can alert workers before the problem becomes more severe. This can allow for faster resolution of issues and reduce the potential for project delays and overruns.

Overall, the use of automation in construction can provide significant cost savings and financial benefits. By reducing labour costs, minimizing material waste, and minimizing project delays and overruns, construction companies can improve their bottom line and achieve greater profitability.

Enhanced Safety and Risk Management

Automation can help to enhance safety and risk management in the construction industry. Here are some of the benefits:

Reducing Workplace Accidents

The construction industry is one of the most dangerous industries, with a high incidence of workplace accidents. Automation technologies can help to reduce workplace accidents by eliminating or reducing the need for labour in high-risk tasks such as working at heights or working in confined spaces.

Implementing Advanced Monitoring Systems

Automation can help to monitor construction sites and detect potential safety hazards in real time. Automated monitoring systems enable site supervisors to access real-time data and analytics about construction performance, site conditions, and potential safety risks. This allows for faster response times and ensures the safety of workers and operations.

Ensuring Compliance with Safety Regulations

The construction sector operates under strict regulations, necessitating a vital adherence to safety rules. The integration of automation can guarantee conformity with safety regulations by overseeing process adherence, diminishing the necessity for manual labour, and granting stakeholders access to real-time site condition data and analytics.

Conclusion

The construction industry is rapidly adopting automation technologies, and the benefits are clear. Automation can enhance productivity, reduce costs, and improve safety in the sector. While there may be some challenges in adopting these technologies, their potential benefits are too significant to ignore.